The best CNC machining guide

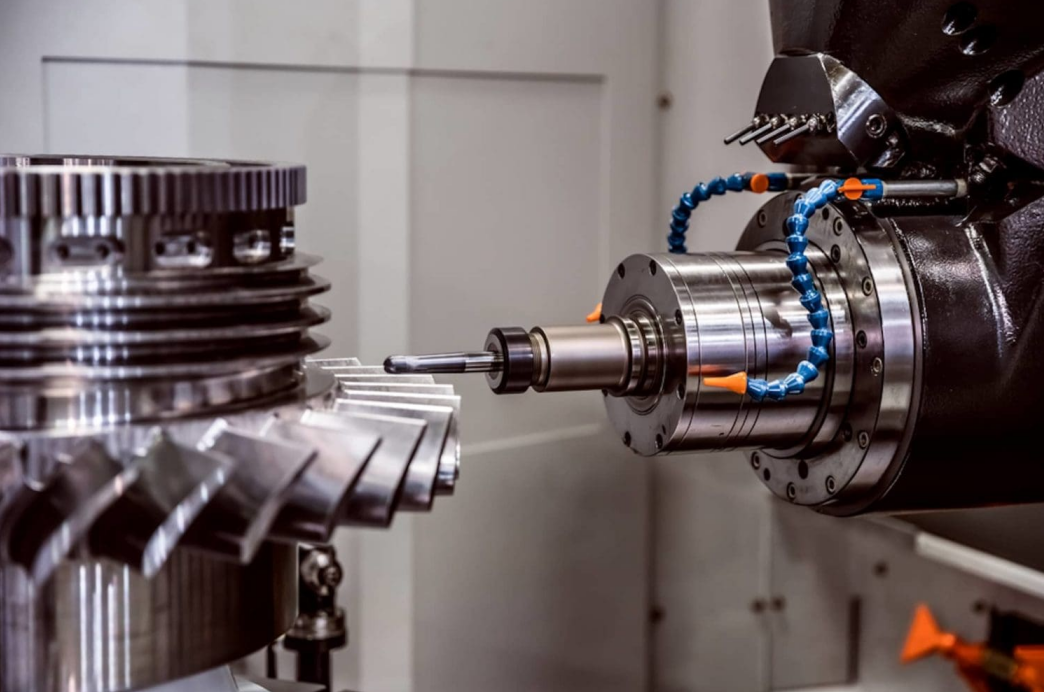

Computer System Numerical Control (CNC) machining is a modern-day, efficient, and automated subtractive production process that allows manufacturers to make repeatable parts of constant high quality from a wide variety of materials, consisting of plastics, metals, as well as compounds. Today, CNC-machined components can be found in a range of various sectors, from aerospace to automotive to clinical.

The beginnings of CNC innovations can be mapped back to a few various factors in background. The first contemporary machining devices appeared in 1775 when industrialists developed an uninteresting tool that permitted suppliers to produce vapor engine cylinders with more consistent levels of precision as well as precision.

The technical forebears of modern-day computing showed up earlier in the century, however, arising from the fabrics sector. In 1725, Basile Bouchon began using a system of punched holes in paper tape to inscribe data. Years later in 1805, Joseph Marie Jacquard fine-tuned the process, exchanging out the paper tape for durable punch cards. When incorporated a series, the punch cards directed how the textile was added to the loom, streamlining the process and supplying one of the very first examples of programs. This device, the Jacquard impend, remains in a method the forebear of our modern computer and also automation services.

This overview to all things connected to CNC machining will go through exactly how modern-day CNC machining refines job, consisting of material choices, layout factors to consider, price motorists, as well as more. Keep reading or go here to download and install the PDF.

Kinds of CNC machining

Today, there are numerous technological procedures consisted of beneath the CNC machining umbrella.

3-axis machining: Milling as well as turning

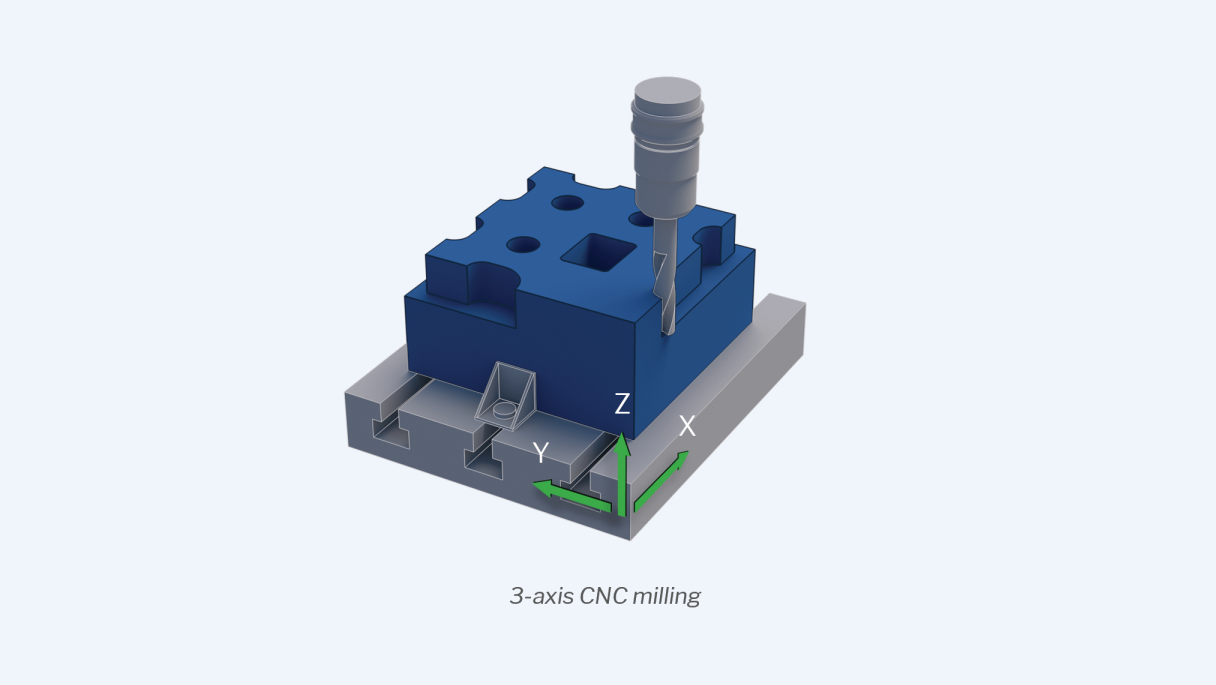

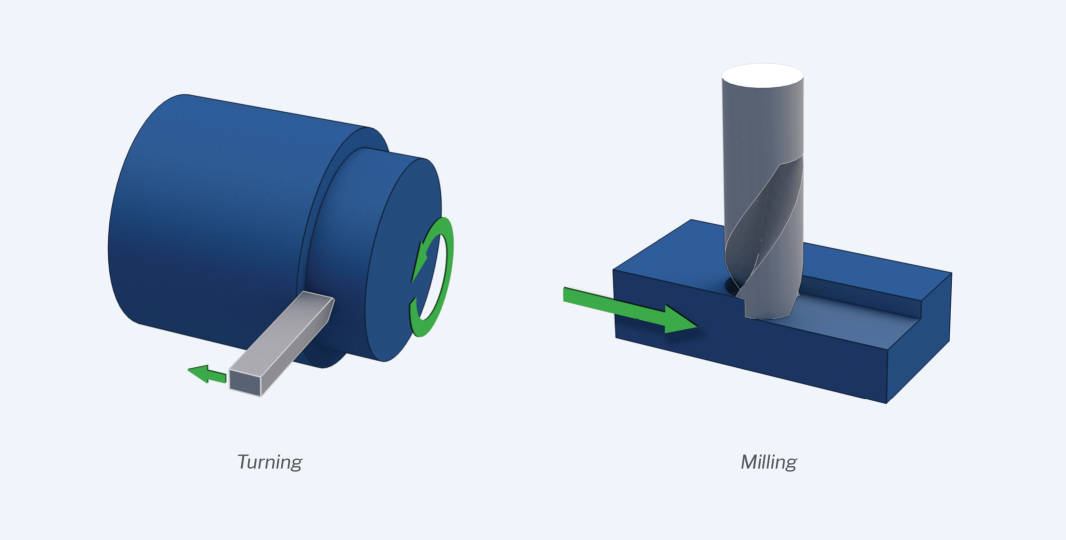

As soon as the driver goes into the machining directions, 3-axis CNC devices will certainly execute the input procedures by utilizing cutting tools to cut along three axes: X (left to right), Y (front to back), and also Z (up-and-down). CNC milling and also CNC switching are two common instances of 3-axis machining.

3-axis CNC milling includes fixing the block of material-- likewise called the work surface or "blank"-- with a vice or equipment bed. This holds the work surface fixed as reducing tools and turning drills, connected to a central pin, make cuts to get rid of material and also form the last component. The 3-axis CNC milling makers are simple to program and also operate as well as can be made use of to develop most parts with straightforward geometric layouts.

Considering that the cutting tools and also drills are restricted to three axes, some style attributes or locations of the space might be hard to finish or get to (e.g., unconventional forms or deep, slim cavities). Nevertheless, several arrangements can help orient the workpiece for the machines to get to these functions. While almost every 3-axis machining work has greater than one arrangement per component, a lot of configurations per component can rapidly enhance manufacturing prices. Processing geometrically complicated components can, for example, call for operators to manually reposition workpieces, which can affect processing rate, rise labor-related costs, and develop more chances for human error.

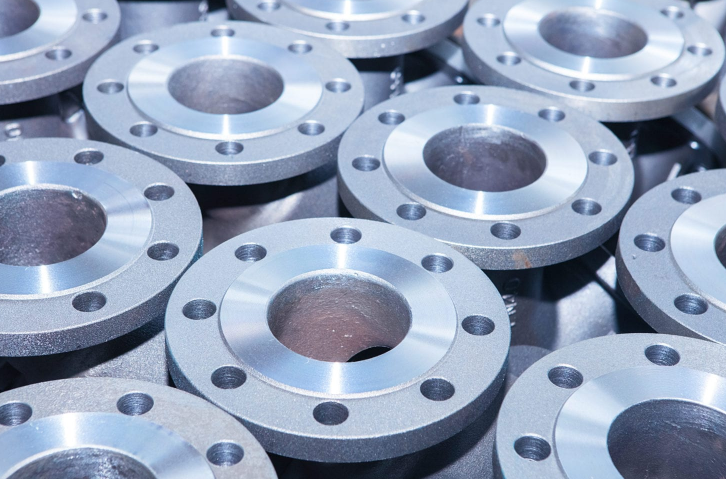

The CNC turning procedure operates a little in a different way. The blank is fixed to a turning spindle, and a lathe after that forms the item's inner as well as outer borders or bores holes around the work surface's facility axis. One of the most considerable style restriction with CNC lathes is that they always generate rotationally balanced parts. The procedure is ideal, therefore, for the production of parts such as screws, bowls, or chair legs. For these kinds of rounded components, turrets can create pieces faster and at reduced prices than CNC milling devices, particularly when producing components in high quantities.

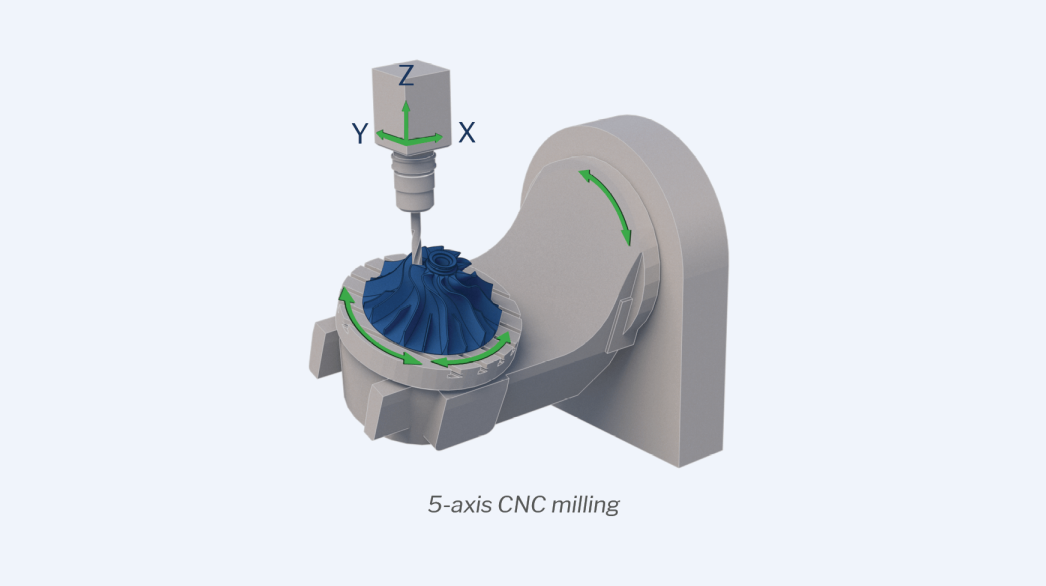

5-axis or multi-axis machining

Multi-axis machining procedures allow the cutting implements better freedom of motion while the workpiece is crushed or transformed. 3-axis procedures enable either the empty or the reducing tool to turn, however not both. On the other hand, 5-axis processes enable both the work surface and the tool to rotate and also move along the X, Y, and also Z axes concurrently. 5-axis CNC machining saves time and also is suitable for producing complex and accurate components like those located in the clinical, oil and also gas, and also aerospace sectors.

The multi-axis CNC machining family consists of three processes:

Indexed 5-axis CNC milling: Throughout indexed 5-axis milling operations, not just can the cutting tools move along the 3 linear axes, yet between procedures, the machining table and device head can swivel in 2 instructions. The most noteworthy benefit of 5-axis milling is that the blanks no longer require to be by hand adjusted between cutting procedures, which makes it possible to create elements with complex geometries much more accurately as well as with higher efficiency. Indexed 5-axis machining is fantastic for fabricating components like housings, jigs, as well as fixtures. The procedure falls somewhere between 3-axis CNC milling and also constant 5-axis CNC machining (see listed below) in terms of speed, accuracy, as well as the capability to handle intricate geometries.

Constant 5-axis CNC milling: Continuous 5-axis CNC milling equipments can relocate and rotate both the cutting tool and the workpiece simultaneously throughout each procedure, permitting the manufacture of get rid of extremely detailed geometries and smooth surface areas. While this is the most costly kind of CNC machining on a per-part basis, the price of continuous 5-axis CNC milling is usually offset by enhanced surface area coating, speed, as well as dimensional security.

Mill-turning machining with online tooling: Mill-turning integrates aspects of CNC lathe equipments with milling tools. The work surface is attached to a turning pin while reducing tools get rid of material from the blank. By incorporating the elements of CNC lathe equipments with milling tools, mill-turning CNC supplies high levels of precision and geometric convenience, making it excellent for creating parts with loosened rotational proportions, such as camshafts or centrifugal compressors.

Choosing the ideal type of CNC machining

When selecting a manufacturing procedure for your component, you'll need to evaluate if it's a better suitable for 3-axis or 5-axis machining. Generally, parts with simpler layouts can be made rapidly as well as economically using 3-axis equipments, while 5-axis equipments are much better for producing geometrically intricate items with boosted rate as well as precision.

If you get on a budget plan or require to reduce a flat surface area, 3-axis equipments are the way to go. In addition to being extra affordable, 3-axis machines are less complex to program, so you will not have to sustain the cost of collaborating with expensive 5-axis designers and also operators. And also, prep time is much shorter with 3-axis machining.

If you need to create a deeper part or one with complex geometry, you'll wish to utilize 5-axis machining. Making use of 5-axis makers allows you device the workpiece from all sides with no hands-on rotation needed. With 5-axis machining, you'll have higher yields, higher accuracy, as well as boosted flexibility of motion, as well as the capacity to manufacture majorities faster.

Typical CNC materials

One of the benefits of CNC machining is that the process works with many different products, plastics as well as metals being the two most typical product family members. Here are a few of the plastics and also steels you're most likely to encounter.

High-performance polymers

Acrylonitrile butadiene styrene (ABDOMINAL MUSCLE): abdominal is an impact-resistant design polycarbonate with outstanding mechanical residential or commercial properties. Strong and also stiff while retaining a level of adaptability, abdominal is notable for being mechanically strong, providing great insulation, as well as being resistant to abrasion and also pressure.

High-density polyethylene (HDPE): Among one of the most functional polycarbonate polymers about, HDPE is an adaptable as well as easy-to-process material that is extremely immune to tension breaking, chemicals, as well as corrosives-- even at low temperatures. It additionally offers superb effect stamina. HDPE is commonly utilized to make plastic bottles, plugs, seals, insulators, piping, as well as lots of other goods.

Low-density polyethylene (LDPE): Mostly utilized to develop orthotics and also prosthetics, this hard, adaptable plastic is simple to bond as well as heat seal. While offering good chemical resistance, LDPE is not ideal for applications that require stiffness, high architectural strength, or high-temperature resistance.

Polyamide (PA) or Nylon: Nylons are a household of low-friction plastics that are well-suited for replacing steel components, like bearings or bushings, due to its distinct mix of elasticity, strength, and also stiffness. Nylons can be reinforced with a range of additives to produce details material and chemical residential or commercial properties or combined with other plastics for enhanced efficiency and product attributes.

Polyamide () or Nylon 30% GF: Glass fibers, one of one of the most usual ingredients for design plastics, dramatically boost the stamina as well as rigidness of nylon components. However, these fibers likewise enhance the brittleness of the material and are therefore suggested only for applications that do not include high-impact stress or deflection.

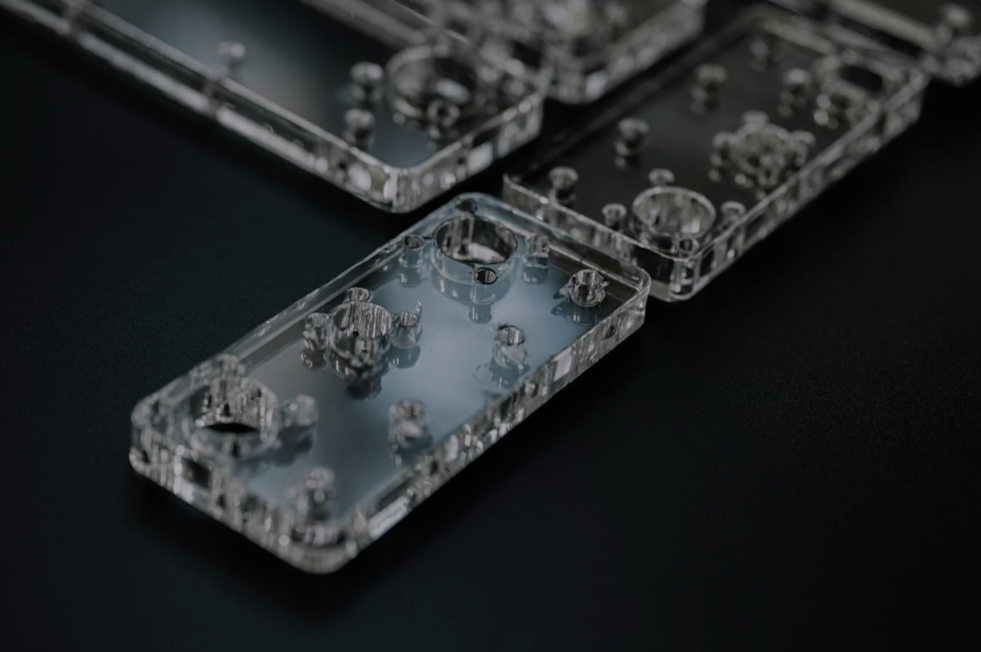

Polycarbonate (COMPUTER): This plastic is commonly made use of for a number of factors-- it's tough while still being lightweight, it's a good electric insulator, and it's naturally warmth immune. Computer is naturally transparent as well as transparent as well as handles pigment well. Furthermore, computer is resistant to diluted acids, oils, and also oils, however is vulnerable to hydrocarbon wear as well as UV rays.

Polyetheretherketone (PEEK): A high-performance polymer with a special mix of mechanical homes, PEEK is chemical-, wear-, creep-, tiredness-, fluid-, and also temperature-resistant. In addition to being recyclable as well as biocompatible, this product is also lightweight, strong, and insoluble in all usual solvents. Similar to nylon, PEEK can change steel in CNC machining. Typical applications for this material consist of piston devices, vital airplane engine parts, and dental syringes. Notably, it is just one of the much more expensive CNC machining plastics on the market.

Polyetherimide (PEI): Commonly referred to as ULTEM ®, PEI is a high-performance plastic and manufacturing staple. Not only is PEI strong as well as easy to use, yet it's likewise immune to chemicals as well as fire, and can withstand very high temperatures without losing its stable electric residential properties. Therefore, PEI is generally utilized to produce products like circuit boards, eyeglasses, food preparation as well as sanitation equipment, as well as aircraft components. It is among the few readily offered amorphous polycarbonate polymers that maintains its mechanical stability at high temperatures.

Polymethyl methacrylate (PMMA): PMMA is a stiff thermoplastic polymer commonly called acrylic or acrylic glass. Very shatter-resistant, this difficult and light-weight material is translucent as well as resistant to weathering and UV light, making it perfect for low-stress applications like greenhouses, the covers of cars and truck lights and also turning signals, or solar panels. Nonetheless, it is necessary to note that PMMA is susceptible to high warmth, impact, wear, and also abrasion, and also it's prone to cracking under heavy lots.

Polyoxymethylene (POM): Generally referred to as Acetal or by its well-known name, Delrin ®, this semi-crystalline engineering-grade polycarbonate offers outstanding dimensional stability, tightness, and low friction. As a result of these buildings, acetal is commonly made use of to create highly specific components made use of in applications where high toughness, toughness, as well as vast operating temperature level variety (-40 ° C to 120 ° C )are required.

Polypropylene (PP): This economical plastic is light-weight, extremely immune to chemicals in destructive atmospheres, and also immune to most natural solvents, degreasing representatives, and electrolytes. Compared to LDPE and also HDPE, PP has a reduced influence toughness but supplies better tensile strength.

Polytetrafluoroethylene (PTFE): PTFE, typically called Teflon ®, is a versatile polymer preferred for its mechanical buildings. Resistant to chemicals, temperature, light, UV rays, water, weathering, fatigue, as well as bond, PTFE is typically discovered in the coverings of nonstick frying pans however is likewise made use of in semiconductors, gaskets, and also some medical applications. Although PTFE is one of the most corrosion-resistant plastics, it's sensitive to slip as well as abrasion.

Polyvinyl Chloride (PVC): PVC is just one of the globe's oldest plastics. Stark white as well as rigid, PVC is an economical rubber option that has remained in high need for decades. Flaunting strong resistance to light, chemicals, and also deterioration, PVC is a popular product in the health care, IT, transportation, fabrics, and also construction sectors.

Ultra-high molecular weight polyethylene (UHMW): A hard, versatile, as well as extremely machinable plastic, UHMW can be utilized to produce get rid of high abrasion and also wear resistance, toughness, and also reduced rubbing coefficients. UHMW isn't usually matched for high load-bearing applications or problems surpassing 80 to 100 ° C.

Metals

Steels and also stainless-steels, aluminums, and soft metals like brass, bronze, titanium, and also copper are among the most popular machinable steels. While steels and aluminums are one of the most generally machined, each family of steels supplies a different set of physical homes and price factors.

Aluminums: Aluminums are soft, low-density, non-magnetic steels that are a lot easier to equipment than steel. As a result of their low tensile strength, these metals are typically alloyed with various other products in order to highlight preferred physical properties. Aluminums are typically around 1/3 the weight of steel, implying that they provide a much better strength-to-weight ratio. This can be helpful in lightweighting parts. They are likewise better thermal and also electrical conductors than steels.

Steels: Steels are iron-based steels that have been alloyed with carbon as well as other steels, normally consisting of manganese, phosphorus, or sulfur. Steels have a tendency to be stronger and a lot more long lasting than aluminums. However, they are additionally heavier and harder to equipment without making use of carbide or various other specialty devices, which can raise production costs.

Stainless steels: The key distinction in between steels as well as stainless steels is that the latter is alloyed with chromium as opposed to carbon. While conventional steels are susceptible to rust as well as rust when exposed to moisture and also oxygen, the chromium content in stainless steels creates a passive chromium-oxide layer on the surface of the metal, preventing the iron within from oxidizing better. This also hinders steels' ability to perform power. Stainless steels can be alloyed with other metals (including molybdenum, nickel, or titanium) to raise a component's resistance to corrosion and warm.

Soft steels: Soft steels like brass, bronze, titanium, as well as copper use a wide range of physical characteristics that are eye-catching for particular applications. Nevertheless, soft metals-- particularly those with high copper web content-- may in fact be more difficult to equipment due to copper's high ductility. Machining soft metals can contribute to enhanced warm accumulation at the cutting website, better device wear, and also galling (a gummy build-up on the device's cutting side). Titanium, specifically, is additionally much less rigid than various other metals and also therefore calls for a tight grip on the workpiece to make sure precision as well as precision. Every one of these aspects can add to greater machining expenses for soft steels.

CNC surface area coatings and post-processing

After a part or element has been machined, it might require to undertake one or more ending up processes. These processes can be made use of to remove visual flaws, improve an item's appearance, offer additional strength as well as resistance, change electrical conductivity, as well as more. Usual completing procedures for machined components are plating, powder layer, as well as bead blasting. However, it is also typical to leave parts as-machined or as-milled when other finishes are not necessary.

Usual CNC completing alternatives

Plating (light weight aluminum): Anodizing is an electrochemical process in which light weight aluminum or titanium alloys are immersed in an electrolytic bath in order to thicken a machined component's natural oxide layer to make it denser, electrically non-conductive, as well as more long lasting. Anodized finishes also promise excellent dimensional control, that makes them best utilized in high-performance design applications, specifically for inner dental caries as well as little components. Anodizing deals among the most cosmetically pleasing finishes for CNC machined parts, however it comes at a greater rate.

Grain blasting (steel or plastic): Grain blowing up makes use of a pressurized air system to fire millions of glass beads at the part, which efficiently removes tool marks as well as imperfections, and can be used to create a consistent grainy, matte, or satin surface coating. Bead blasting adds no chemical or mechanical buildings and, unlike powder finish which adds material to a part, it's a reductive finish, meaning that the process gets rid of material from the component. This is an important consideration if your component has strict tolerances. Bead blasting is among one of the most budget-friendly surface area finishes yet must be performed by hand. Bead size and also grade will additionally impact the last coating.

Black oxide (steel, stainless steel, copper): This electrochemical or chemical treatment procedure develops black iron oxide on the surface of ferrous metals. Also called smudging, oxidizing, or black passivating, this procedure does not just deposit a black oxide layer on the surface of the metal. Instead, the chemical reaction in between the iron in the steel as well as the oxidizing salt remedy produces an iron oxide called magnetite, which has a matte black look. This procedure enhances the part's dimensional security and aesthetic appearance while minimizing the surface area's light representation, which is very important for components utilized in applications including radiation. Black oxidizing steel can also assist develop tools like screwdriver ideas as well as drill bits.

Powder coating (all metals): Powder layer is similar to spray painting. The machined part receives a primer coat to safeguard it versus rust. After that, the part is "repainted" with a dry powder layer from an electrostatic spray gun and also treated in a stove heated to a minimum of 200 ° C. Numerous layers can be put on enhance the thickness of the coating, which produces a thin safety layer on the component that is solid, wear-resistant, as well as cosmetically pleasing. This process can be integrated with bead blasting to raise the component's deterioration resistance as well as develop higher uniformity in structure and appearance. Unlike anodizing, a powder-coated coating is compatible with all steels, is less breakable, and also offers better influence resistance. However, powder coating typically generates less dimensional control than an anodic finish as well as is not suggested for usage in little elements or internal surface areas. Powder layer's higher cost point can likewise make larger manufacturing runs pricey.

As-machined (metal or plastic): Not using completing procedures to machined components is referred to as an "as-machined" or "as-milled" coating. The component will have little but noticeable device marks and blemishes. As-machined parts have the tightest dimensional tolerances as well as are very cost effective to produce due to the fact that post-processing isn't essential. This is ideal for applications in which dimensional stability issues more than aesthetics. Nonetheless, it's important to keep in mind that without extra finishing or protective covering, the surface firmness of as-machined makes them prone to nicking, scuffing, as well as scratching.

Choosing the ideal materials as well as finish

Choosing products and also post-processing choices for your part depends greatly on how and also where your component will certainly be made use of. Key end-use factors to consider for picking your component material as well as surface finish consist of:

Ecological elements: The ecological conditions of an offered part's end-use application play a significant role in determining which materials and also therapies are ideal. Aspects like heat, cold, flame, UV radiation, exposure to chemicals or autoclaving, as well as extra should be taken into consideration in order to make sure the viability of the component.

Electric variables: Whether a component calls for conductive or protecting residential or commercial properties is an additional important consideration. Understanding your part ought to conduct electrical energy, you may choose a conductive product like copper, whereas a material like Nylon 66 would be appropriate when searching for an excellent insulator.

Mechanical aspects: Components planned to endure hefty tons, wear, or various other external forces need to be made from products that can stand up to those forces. Determining the most preferable or essential buildings for a component-- such as adaptability, influence resistance, tensile or compressive stamina-- can assist teams pinpoint which materials make the best fit.

Cosmetic factors to consider: While aesthetic appeals can be of secondary concern for some parts, this is not the instance for many consumer products. Some parts or applications might require materials with certain aesthetic options when it pertains to shade, openness, or surface finish.

Tolerances: Some degree of variant in between components is expected in production, and also dimensional resistances refer to the series of acceptable variant that feasible parts must fall within. Tighter tolerances are more labor-intensive and also costly to achieve repeatedly but might be essential based on just how an element is made use of.

Designing for CNC machining

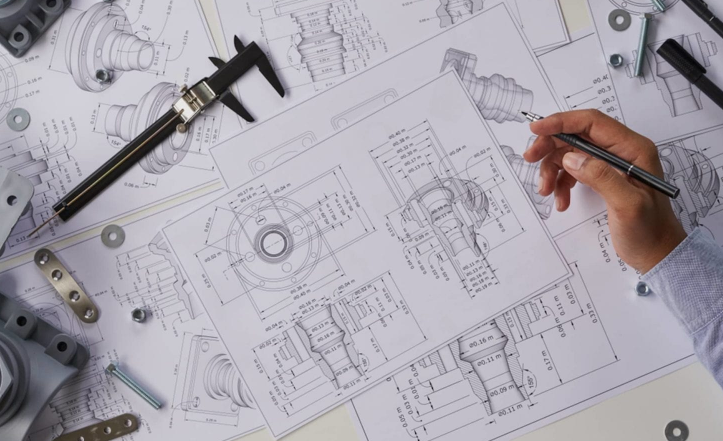

Creating a premium part that will do as expected is just half the difficulty. You need to also have the ability to equipment the component in an effective as well as affordable way. Design for manufacturability (DFM) is the procedure structure that assists incorporate just how a part will be made with the component layout. DFM is vital to manufacturing as well as impacts whatever from manufacturing timelines and prices to functional efficiency as well as the quality of the part itself. One of the most usual style factors to consider for CNC machining consist of:

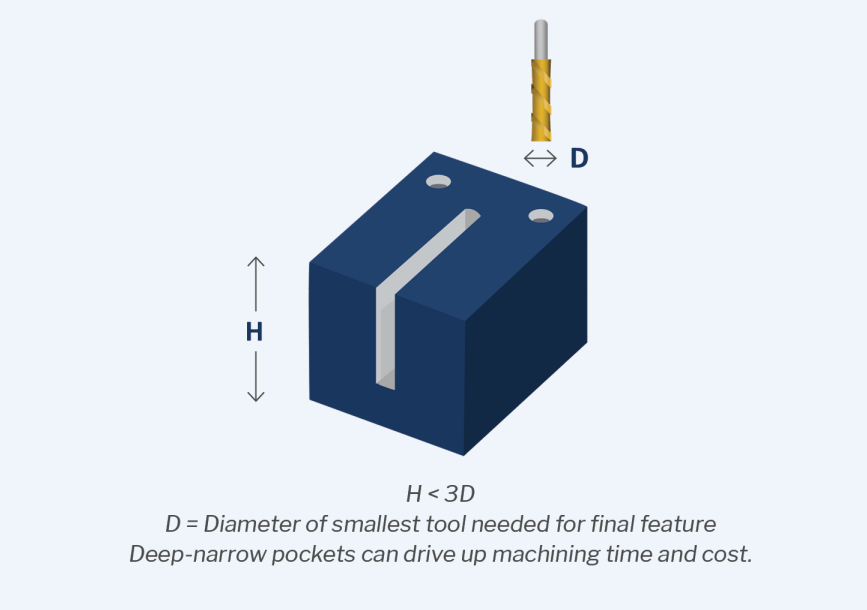

Deep pockets:

Features such as deep or narrow pockets and also slots need longer devices to equipment properly. Nevertheless, longer cutting tools are extra prone to breaking and also are typically much less exact because of machining vibrations, or chatter. Deep functions additionally generally need several cuts to machine appropriately, which raises both machining time as well as production expenses-- particularly given that smaller sized devices will likely be required to complete the finishing passes. If ports or deep pockets need to be machined, purpose to either lower the depth of the function as long as feasible or boost the area of the pocket's cross-section. The deepness of a pocket or slot must disappear than 3x the diameter of the tiniest device needed.

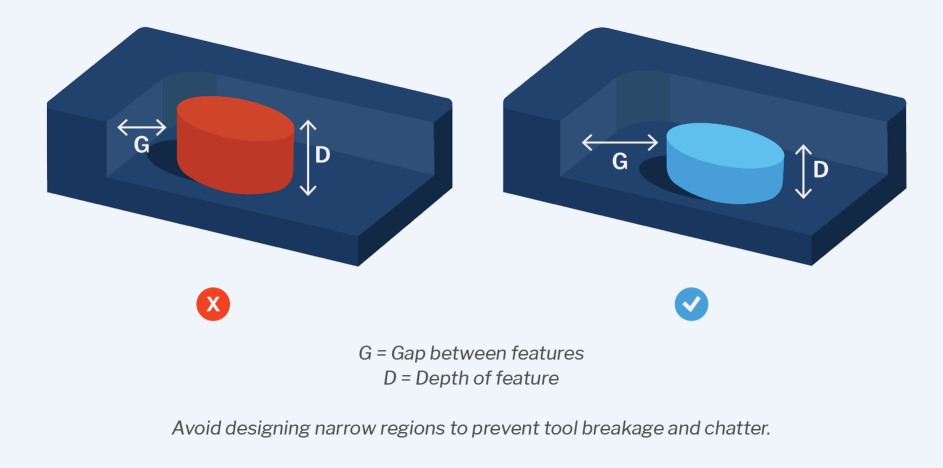

Narrow areas:

Slim functions restrict the dimension of viable cutting tools. This can offer an obstacle for suppliers due to how vulnerable long, small-diameter devices are to chatter as well as breakage. Equally as with deep functions, slim regions should be no less than 3x the size of the tiniest cutting device. Lessening the deepness of these features enables you to make use of shorter, larger-diameter cutting devices, which aids to decrease device chatter.

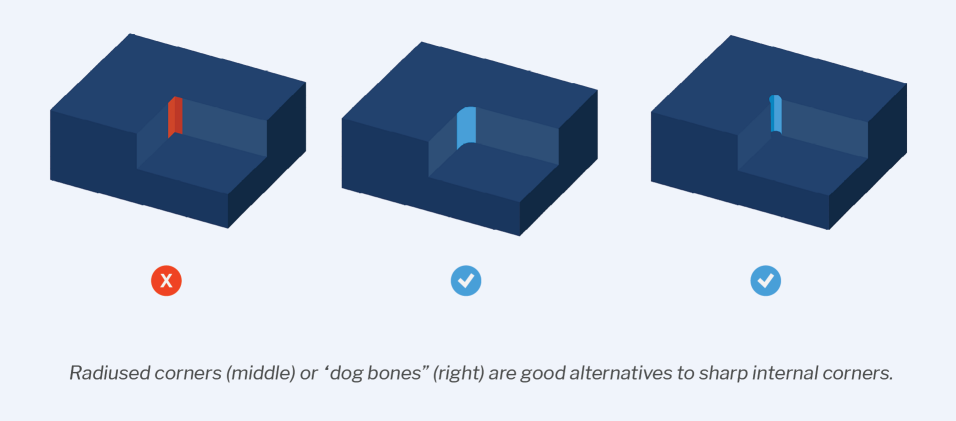

Sharp internal corners:

CNC end mills are circular, which makes it difficult to equipment sharp internal edges since the little bits will leave behind an edge radius. While there are methods of machining sharp internal edges, these processes have a tendency to be expensive. Generally, sharp inner edges should be stayed clear of for machined parts. Interior edge radii should also be larger than the span of the desired cutting tool. Deliberately inner radii to be larger than the reducing device, the maker can produce a smooth change in between wall surfaces. In contrast, an internal radius that coincides size as the reducing tool will certainly compel the equipment to make a sudden change in direction, resulting in a much less smooth finish.

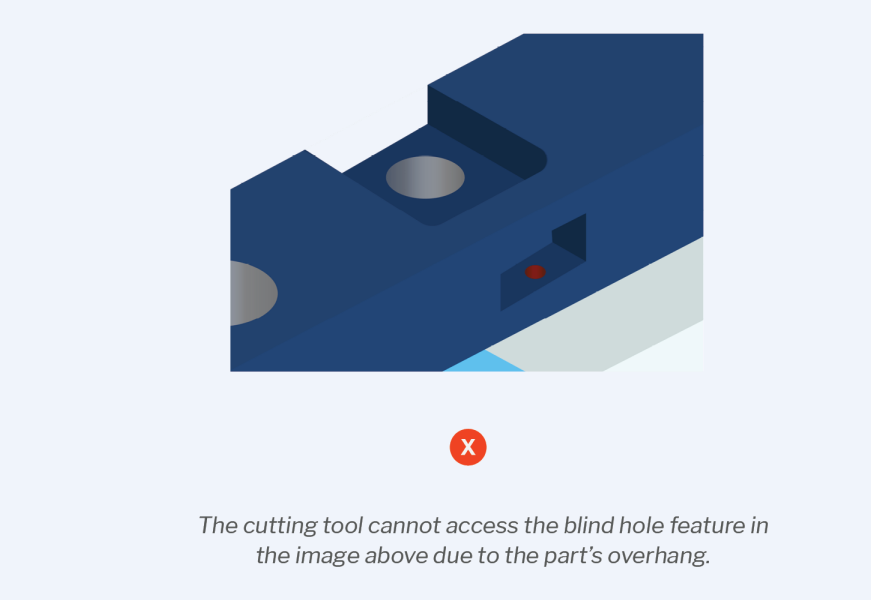

Hard to reach functions:

Features like counterbores-- those that open inside another pocket or pockets with negative drafts-- can pose a significant obstacle for production groups. These style features take considerably more time to device as a result of how difficult it can be to allow the cutting tool access. It's critical to make certain that cutting tools can openly access every one of a component's attributes without being blocked by any other function.

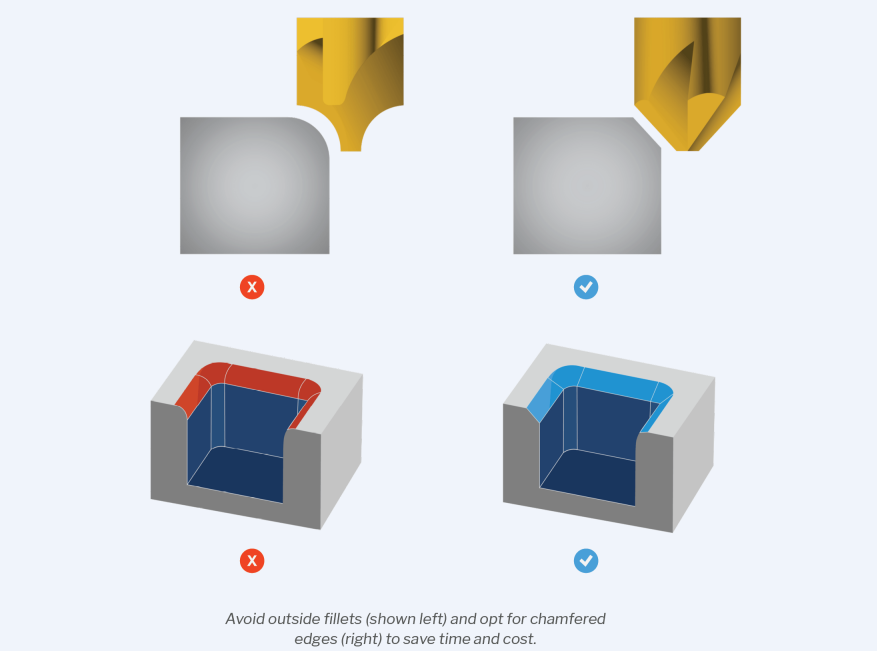

Outdoors fillets:

Outside fillets, or rounded corners along the top side of pockets, bosses, ports, and also other attributes, need custom cutting devices supported by an accurate machining configuration-- a pairing that can swiftly become costly. Beveling or chamfering the outdoors edges can help avoid these expenses.

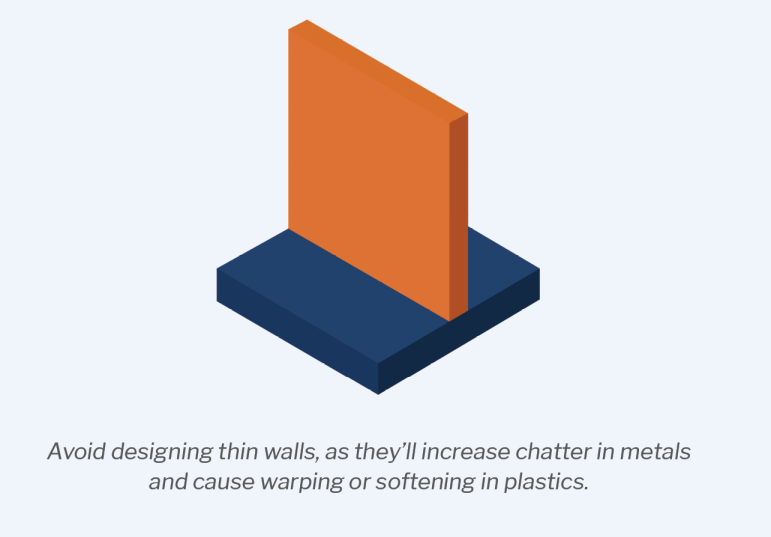

Wall density:

Thin walls can develop concerns for metal as well as plastic components alike and also should be avoided any place feasible. Thin metal walls are a lot more susceptible to babble, for instance, which negatively affects the precision of the part and also its surface coating. Plastic get rid of thin walls are likewise more likely to warp or soften. The minimum wall surface thickness for steel components need to be 0.03" (0.762 mm) and 0.06" (1.524 mm) for plastic components.

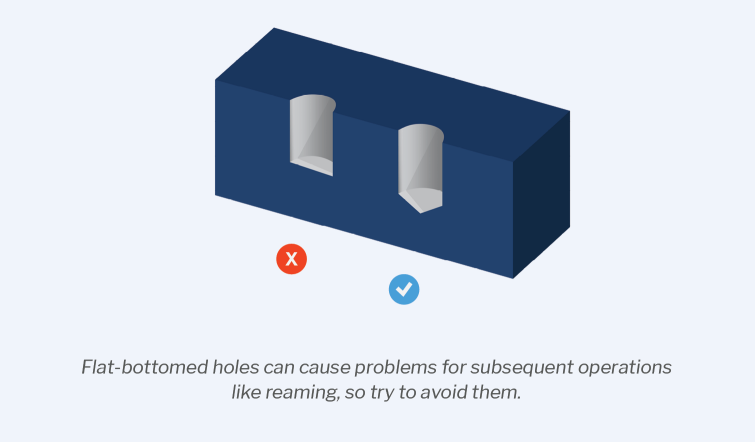

Flat-bottomed holes:

Holes with flat bottoms are not only difficult to device, yet they also tend to develop difficulties for any subsequent procedures. Generally, product groups need to avoid blind holes with flat bottoms in favor of conventional spin drills, which create openings with conical bottoms.

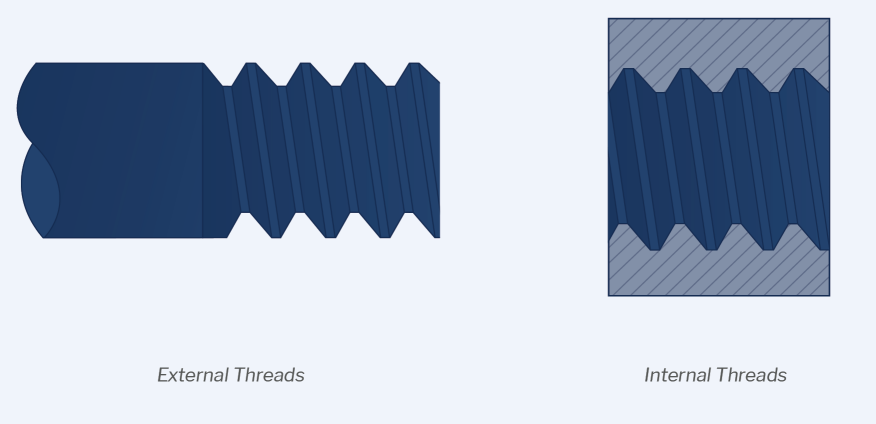

Threaded parts:

When machining inner or exterior threads, there are a couple of different style considerations.

For interior strings:

Consist of a countersink at the end of internal strings.

Minimize the variety of strings whenever feasible. The majority of a component's stress really falls on the first three strings, so boosting the number

of threads creates reducing returns.

Usage typical kinds and also dimensions.

Opt for crude strings to maintain expenses low.

For outside strings:

Include a chamfer in all screw styles.

Avoid ending near the shoulder of areas with big sizes.

Turned exterior strings must have an alleviation groove.

Use much shorter outside threads unless the part specifically asks for high string stamina.

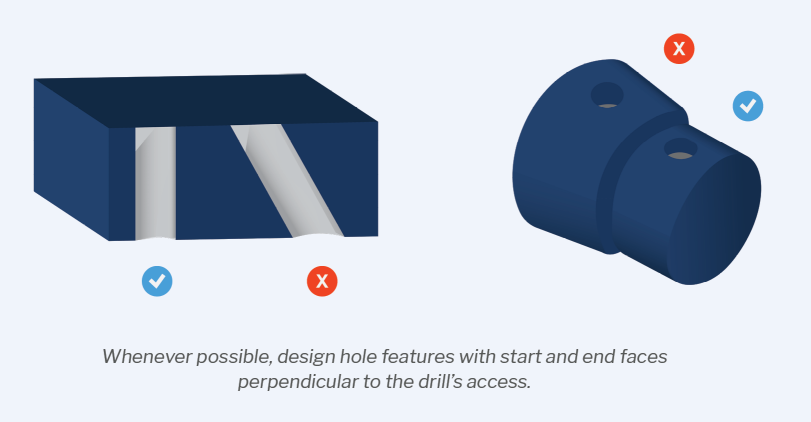

Pierce entries as well as departures:

If the surface area of a work surface is not perpendicular to the axis of a drill, the drill suggestion will certainly wander when it enters contact with the material. To minimize irregular exit burrs and also streamline the burr-removal procedure, make sure that opening functions have begin as well as end deals with that are perpendicular to the drill axis.

A checklist for reducing expenses

1. Keep components easy

Parts with intricate designs or producing procedures can have a number of downstream impacts. Intricacy can raise machining time as well as price, present chances for error, and make it hard for end-users to understand the precise use of elements or components. Separating which features and style features are vital to the viability of the part from those that are preferable yet non-critical helps eliminate unneeded intricacy from a part's design and also machining procedures.

2. Layout with tool geometry and setup positioning in mind

While most CNC machining work require more than one arrangement orientation, you'll want to maintain the number of alignments per component to a minimum. As an example, if you need to turn a workpiece 3 times for the cutting tools to be able to gain access to all of the attributes, this is mosting likely to boost prices because each setup requires re-mounting the part, zero-ing the machine to develop the correct axes, and also running a brand-new G-code program. 5-axis makers are going to be much more qualified in this facet as they can reach more functions without requiring multiple configurations, though this is dependent on the geometry of a certain part.

Decreasing the variety of reducing devices called for is one more way to decrease expenses. As high as feasible, try to maintain radii regular to ensure that less devices are required to equipment internal corners. Likewise, stay clear of very small details where possible. Smaller sized cutting devices aren't able to cut as deep right into the work surface and are also extra susceptible to damaging. Normally, the smallest interior functions that can be machined are 0.0394" (1mm), though openings can go as small as 0.0197" (0.5 mm).

3. Stabilize your resistances

Select your critical dimensions attentively. Not every dimension requires inspection or is crucial to the feasibility of the part, so concentrate your interest on those that are most crucial. Establishing exactly how precise details attributes need to be will certainly allow you to readjust resistances as necessary, decrease prices, and also improve the manufacturing process. Make sure that tolerances are still within machineable limits, stick to provided standards, and also make up resistance stacking.

Avoid over-dimensioning your part, too. Uncertain part illustrations defeat the objective of geometric dimensioning as well as tolerancing, which is to make clear as well as enhance interaction. At JTC Machining, we advise that you align attracting information with the CNC coordinate system, as making use of regular datum reference frames between machining and also dimension systems is more probable to make sure parts are accurately located.

Preferably, make sure all information-- factors, surface areas, or axes utilized as recommendations for measurement-- recommendation the very same arrangement. If a datum was machined in a previous configuration, it ends up being harder to hold tight resistances after a configuration adjustment. Lastly, be mindful concerning your datums. Selecting reference datums that are simple to gauge from will relieve production.

4. Tailor assessment degrees

Comparable to balancing your resistances, purposefully using the right evaluation degrees can help reduce costs and also maximize the production procedures. Normal examination alternatives might include an aesthetic assessment of the component, checking component dimensions utilizing hand tools, or a first short article examination (FAI) where the initial manufactured part is inspected to guarantee all demands have been fulfilled. More thorough evaluations call for even more time as well as labor, which boosts production expenses.

Increasing the variety of parts that you inspect will also increase the price of manufacturing, so it is essential that you pick the appropriate sampling plan to make sure confidence throughout the whole order. At Quick Radius, our default sampling rate is based on ANSI ASQ Z1.4 Degree 2.

5. Style to common stock dimensions

Designing parts to ordinary shares dimensions can assist improve the manufacturing procedure by lessening the amount of product that requires to be eliminated from the work surface. As an example: if it serves for a part surface area to preserve its supply surface-- that is, if the surface area can be rougher than 125 μin Ra-- as well as it does not need to be machined, you have an opportunity to minimize machining time without compromising component top quality.

This is why understanding the common stock sizes for various materials is necessary. Steels, for example, are typically offered in a variety of supply kinds, consisting of sheets, poles, bars, or tubes, which can be bought according to measurements like length, width, thickness, and size.

Keep in mind that metric sizes are a lot more commonly readily available in Asia, while imperial dimensions are extra frequently offered in the U.S.

6. Decrease contortion risk

Removing a huge amount of material from a workpiece can trigger the material to deform. This requires added handling during machining to prevent deformation, bring about higher expenses. Plastics have a higher danger of contortion than steels.

7. Select your material thoroughly

The material you pick has a considerable impact on the general expense of your part. As an example, steels are typically much more expensive than plastics. Prevent over-engineering your components as well as consider whether a details quality or material certification is required for the component. If a generic material can accomplish the part's requirements or numerous materials can be approved, pick the less costly material to keep prices reduced.

The machinability of the material must additionally be thought about. Steels, as an example, are normally more difficult to maker, which causes greater expenses due to the fact that steel parts take longer to machine and also increase wear-and-tear on cutting tools.

Common applications for CNC machining

Many industries rely on CNC machining processes to generate reputable, accurate components that meet specific requirements and also governing demands, consisting of the aerospace, automobile, medical gadget, electronic devices, and also industrial components producing industries.

Aerospace parts are held to top quality, testing, and also governing standards in order to guarantee proper feature, fit, and also safety and security. CNC machining is an exceptional fit for creating plastic and also metal parts with extremely limited resistances that please the aerospace maker's need for an extraordinary degree of accuracy and also a series of very specialized components. The same holds true for auto elements.

CNC machining can additionally be utilized to create a selection of clinical devices, from implants to surgical carries out to elements for medical electronic devices.

Treatment and also precision are essential when producing these kind of gadgets as well as devices, as they are held to added security criteria as well as requirements. Semiconductors and electronic devices elements also have exceptionally strict precision demands as well as tolerance criteria, offered their size and complexity. As a process, CNC machining has few product restrictions, permitting it to be made use of with conductive materials like silicon. Many commercial components-- from aluminum spreadings as well as extrusions to steel and plastic parts-- can additionally be machined.

One more usual application for CNC machining is tooling, or the process of creating the various components, devices, equipment, and also master patterns that will certainly be used in manufacturing. Tooling is an integral part of every manufacturing and also molding process as well as incorporates items like mold and mildews, jigs, and components.

Starting your CNC machining job with Rapid Distance

At JTC Machining, we make it easy and straightforward to obtain quality components via our CNC machining solution. To get going, check out jtc-machining.com, upload your part styles, as well as you'll get instantaneous DFM feedback. The website additionally permits you to take care of styles and orders from a single, instinctive interface.

When you select Quick Span, you're picking to deal with a skilled group of specialists. You'll get the complete support of our group of engineers, client success managers, account executives, and others throughout the business. We'll additionally take advantage of alternatives for residential and worldwide CNC machining to ensure that your project is carried out as successfully as possible, without compromising quality.

Get in touch with us today to experience the JTC Machining difference or click on this link to download our thorough guide as a PDF.