What is complex injection molding?

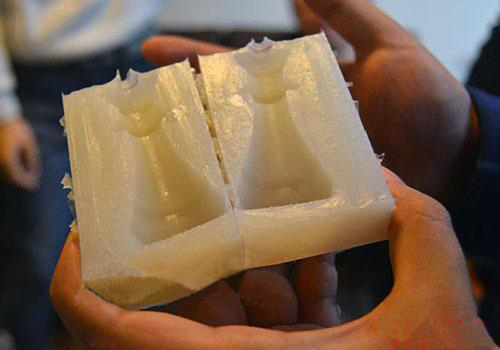

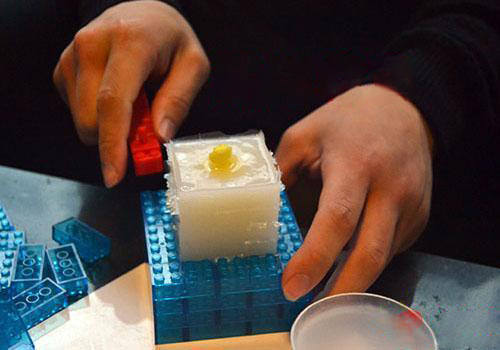

Rapid prototyping complex mold is to produce original mold through precise design manuscript and drawings of any shape. Usually raw materials are: ABS, PP, PA, PE, etc. The range of spray colors is optional, including red, blue, yellow, black, etc. However, compared with the international color value card, the color is still quite different. The manufacturer injects the raw material specified by the customer through the original mold, and quickly produces the replica mold of the same shape and size. This method of repeatedly producing molds through the original mold is called CNC complex molding process.

How do you decide to choose CNC overmolding over 3D printing?

When you need to mass-produce 50x50mm, 80x80mm, 100x100mm plastic models, or other sizes, although 3D printing can quickly make molds, the one-time production and processing costs are high, and it is not suitable for mass or mass production. The complex mold can help you achieve your goal with only one CNC machining cost.

When you need more than 100x100mm size moulds and the demand is only a few pieces. 3D printing is more suitable than complex molding, and both cost and efficiency are more favored by the market.

What are the disadvantages of remodeling?

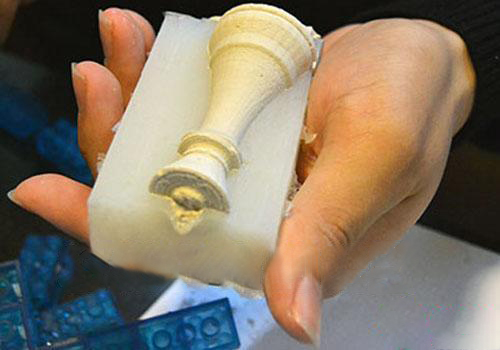

Loss Of Precision

Reusing the original mold will gradually deform the mold in a slow fashion, losing shape and dimensional accuracy. The mold parts copied N times will also lose the size part of the local shape, thus failing to meet the standard. Only in the later stage of secondary processing, the mold parts can meet customer requirements.

Color Value Deviation

The purity of the raw materials used in CNC remolding is not as good as that of ABS, PP, PA, PE, and the composite materials used. The color value reduction degree of the mold parts produced by the original remolding cannot reach 90% of the normal, which will be more obvious compared with the international color card. It can be colored by later inkjet processing to make the color more in line with the international color card value.