What is Selective laser sintering (SLS)?

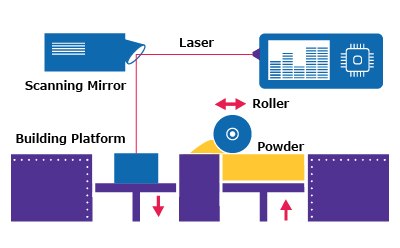

Selective laser sintering (SLS) is a 3d printing process (additive manufacturing) that uses high-powered lasers to sinter, or bind, finely powdered material together into a solid structure. In this process, a printer lays down an even layer of powder and then precisely sinters that layer, repeating the deposition and sintering process until the part is complete. The shape of the object is created by aiming a laser at the powder bed in specific points in space, guided by a digitally produced CAD (computer-aided design) file.

Unlike selective laser melting (SLM) which fully melts particles together, sintering causes an atomic reaction that fuses particles, turning powdered material into a solid structure. The term SLS is typically only used to refer to plastic and ceramic 3D printers — metal 3D printers using a similar process are referred to as DMLS or SLM machines.

SLS machines can produce high fidelity items, including precision, low volume parts in automotive and aerospace fields. SLS can produce large or geometrically complex, intricate, and highly accurate parts from a variety of materials.

SLS Printing Advantages and Disadvantages

Rapid Prototyping Parts with SLS saves money by reducing the need for molds, CNC bandwidth, or any other method of creating high-fidelity parts. Parts can be printed quickly on demand, which allows quick iteration. Also, SLS parts are isotropic, meaning they have equal strength in every direction, which is not always the case with layered 3D printed objects.

SLS is an excellent printing technology, but it has high barriers to entry. Machine cost and maintenance costs are expensive (among the most expensive when compared to plastic printers), and they require skilled operators. They also can only produce plastic-strength parts.

History of SLS Printing

The SLS process was developed and patented by Dr. Joe Beaman and Dr. Carl Deckard at the University of Texas in the mid-1980s under the sponsorship of DARPA. Deckard and Beaman were involved in the founding of one of the first 3D printing startups, Desktop Manufacturing (DTM) Corp., in 1989, which was sold in 2001, to 3D Systems.

|

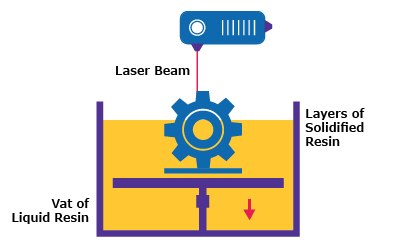

Stereolithography Printing Process |

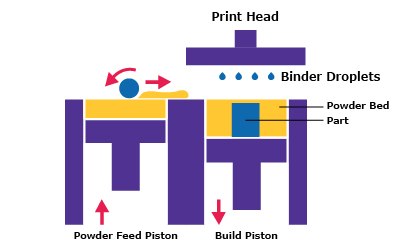

Binder Jetting 3D Printing Process |

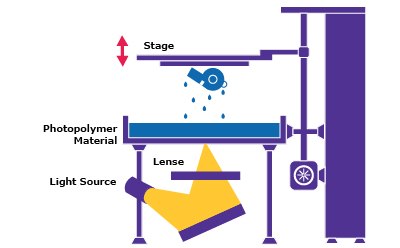

Digital Light Processing(DLP) 3D Printing Process |

|

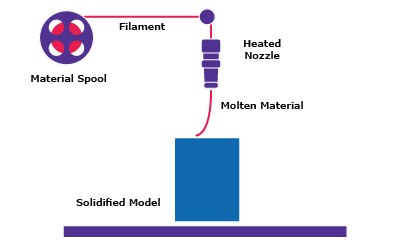

Fused Deposition Modeling(FDM) Printing Process |

Power Bed Fusion 3D Printing Process |

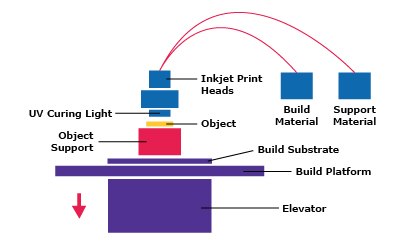

Material Jetting 3D Printing Process |

Industry Application

In China, we work with clients from all industries including aerospace, automotive, consumer products, and OEM customized products, such as healthcare and special machinery. With our SLS 3D printing service in JTC, we're able to produce detailed products including robotics, jewelry and watches, sports or athletic equipment, and more. Architectural and construction companies benefit from SLS 3D printing services as well to create architectural replicas and detailed concept models at a moderate price.

FAQ

What is sintering?

Sintering is the act of using heat, compression, or a high-powered laser to make a powdered material coalesce into a solid structure. It is distinct from melting as no phase change occurs.

What materials can be sintered with a laser?

Sintering can be applied to powdered glass, plastic, concrete, ceramic, and other materials.

What is the difference between SLS vs SLA?

SLS atomically fuses powdered industrial materials together using a high-powered laser; SLA fuses powdered materials together by heating them until they reach a melting point. Sintering temperatures typically run at about 85% of a material’s melting point.

Why use SLS vs SLA?

The processes are similar, but SLS is to produce parts made from various plastics, glass, or ceramics; SLA is commonly used in manufacturing metal or metal alloy parts.

What is the difference between annealing vs sintering?

Annealing is a post-processing step in which a solid piece of metal is heated to a temperature below melting and then allowed to cool slowly, increasing its flexibility and changing it in other ways. Sintering is a technique that heats powdered substances at a temperature below the melting point, and maintaining that heat until the particles join by atomic fusion, creating a solid mass.