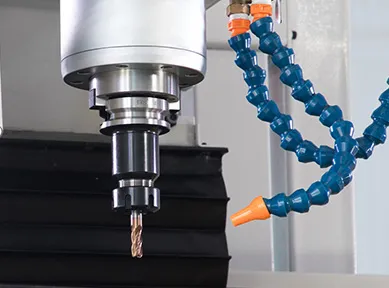

3 4 and 5 axis machining capabilities suitable for simple and complex parts machining.

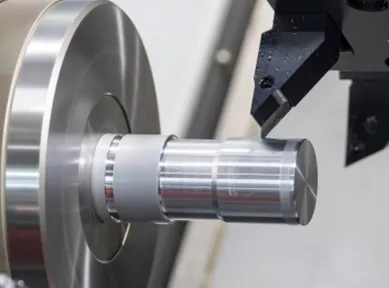

Standard and power accessory functions for cylindrical parts (such as pins shafts and washers).

Parts are brushed and then anodized type II. Ideal for increasing the corrosion resistance of the part. Typically results in a glossy color.

Parts are sandblasted and anodized Type II. Ideal for improving the corrosion resistance of parts. The result is a natural matte color. For glossy colors choose the brushed anodized option.

FDIS09001-2015A

IATF-16949

ISO-27001

FDIS09001-2015A

IATF-16949

ISO-27001

FDIS09001-2015A

IATF-16949

ISO-27001

FDIS09001-2015A

IATF-16949

ISO-27001

FDIS09001-2015A

IATF-16949

ISO-27001

FDIS09001-2015A

IATF-16949

ISO-27001

FDIS09001-2015A

IATF-16949

ISO-27001

FDIS09001-2015A

IATF-16949

ISO-27001

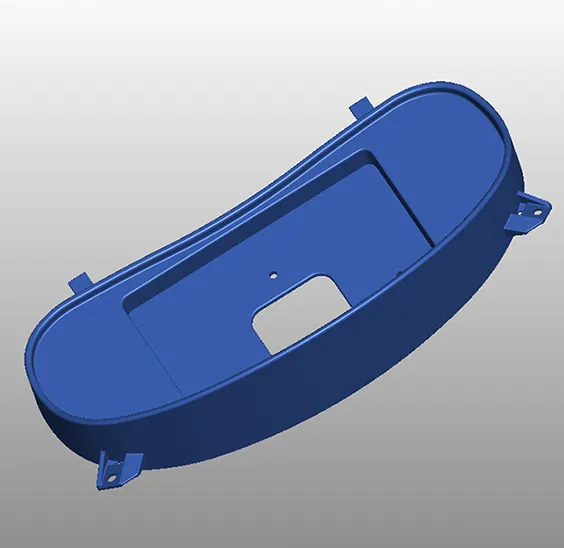

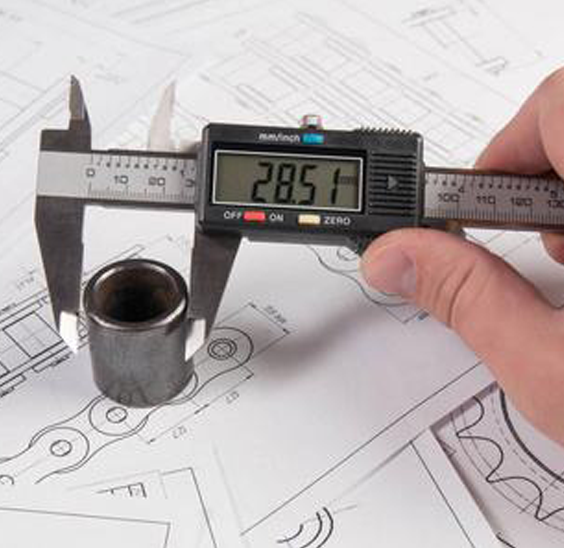

First of all we need to receive your 3D drawings (stp step igs iges format) and quote according to your needs such as quantity material surface finish etc.

Before the mold is assembled to the injection molding machine the drawing needs to be programmed so that we can clearly see the process of the material as it enters the mold for further adjustments and modifications.

According to the design drawings it is put into CNC processing and production. Strictly control errors and skilled operators for more than 5 years control the quality.

After the mold is complete it is assembled into the injection molding machine. During the injection process we check that the machine is functioning properly (or not) make some necessary tool adjustments and generate a new sample.

After the samples are surface treated as specified by the customer they will be checked again for dimensions.

According to customer requirements choose the surface treatment method. At the same time quality inspection work is carried out.

The last step is to check whether the mold needs to be adjusted according to the analysis of the sample and whether the test sample meets the previous requirements.

After the samples have been tested to meet the preliminary requirements the samples can be packaged and shipped.

CNC is the abbreviation of Computer Numerical Control. CNC machining is any kind of machining process controlled by a computer. Computer automation can manufacture parts faster more accurately and more precisely than parts produced by manual machining better suited to complex geometries. CNC also reduces the amount of manual machining work that would otherwise be done by humans. While they don't machine every part themselves people are critical to the programming and operation of the machinery to ensure that every operation runs smoothly.

Programs now used for CNC machining are written in G-code and are usually created automatically by CAM software. CAM or Computer Aided Manufacturing software produces G-code for a 3D model for a given tool and workpiece material. This G code controls the CNC machine i.e. the movement of the tool workpiece and any tool changes. It even has commands to turn the coolant and other auxiliary components on or off. CNC machining can be used on a variety of materials the most common being aluminum steel brass ABS Delrin and nylon. But in fact almost any hard material can be CNC machined.

CNC or Computer Numerical Control Machining is a subtractive manufacturing method that uses a combination of computer control and machine tools to remove layers from a stationary material. The desired cuts in the metal are programmed according to the corresponding tools and machines which perform the machining tasks in an automatic manner.

Depending on the type of part that needs to be machined there are different types of CNC machines that are best for the job. CNC milling uses CNC milling machines that consist of multi-axis systems (3 4 or 5 axes depending on part complexity). CNC turning involves a lathe which usually has 2 axes and uses a circular motion to cut the workpiece. An electrical discharge machine (EDM) uses electric sparks to form a workpiece into the desired shape. Gear hobbing is another machining process used to cut gears splines and sprockets. Other CNC machine types include plasma cutters and water jet cutters.

CNC machined parts are more functional and generally have superior production quality and finish compared to part manufacturing via additive manufacturing. Therefore CNC machining is often used in the mid to late stages of development when the part is ready for functional accuracy testing.

While most details such as tooling spindle speed tool type and depth of cut are handled in the machine shop there are some key things you can do when designing your parts not only to make sure they are manufacturable but also to make sure you Develop lean products that won't break the bank.

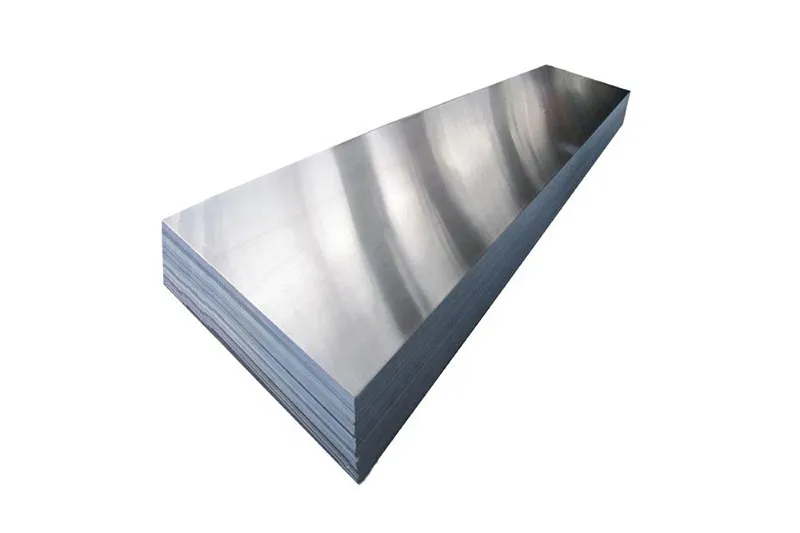

Aluminum is one of the most commonly used metals in the world because of its excellent strength-to-weight ratio low cost and recyclability. Mill Lead Time: As fast as 3 days Alloys: 6061-T6 7075-T6 7050 2024 5052 6063 MIC6 Finishing Options: Alodine Anodizing Types II III III + PTFE ENP Media Blasting Nickel Plating Powder Coating Tumble Polishing.

Consult now

JTC offers both alloy and carbon steel options useful for a variety of applications including fixtures mounting plates draft shafts axles torsion bars gears bolts studs shafts and structural applications. Mill Lead Time: As fast as 3 days Alloys: 4140 4130 A514 4340 Carbon Steel Types: 1018 Low Carbon 1045 Carbon Zinc-Galvanized Low-Carbon Finishing Options: Black Oxide ENP Electropolishing Media Blasting Nickel Plating Powder Coating Tumble Polishing Zinc Plating

Consult now

Stainless steel is highly resistant to corrosion and rust making it suitable for situations where a part may be exposed to the elements for long period of time. Stainless steel is also fairly malleable and ductile. Mill Lead Time: As fast as 2 days Finishing Options: Black Oxide Electropolishing ENP Media Blasting Nickel Plating Passivation Powder Coating Tumble Polishing Zinc Plating Alloys: 303 304L 316L 410 416 440C 17-4PH Nitronic 60

Consult now

360 Brass also known as free machining brass is commonly used for a variety of parts including gears lock components pipe fittings and ornamental applications. Mill Lead Time: As fast as 3 days Finishing Options: Media blasting

Consult now

932 Bearing Bronze is a high strength alloy with good wear and corrosion resistance due to its tin iron and zinc content. Mill Lead Time: As fast as 3 days Finish Options: Available as-machined media blasted or hand-polished

Consult now

Cast iron is a dependable wear-resistant material that’s ideal for absorbing vibrations. Great for gears bases pulleys and bushings. Mill Lead Time: As fast as 7 days Finish Options: Media blasting Tumbling

Consult now

101 and 110 copper alloys offer excellent thermal and electrical conductivity which makes them natural choices for bus bars wire connectors and other electrical applications. Mill Lead Time: As fast as 3 days Finishing Options: Available as-machined media blasted or hand-polished Alloys: 101 110

Consult now

Titanium may be selected over other materials such as steel due to its ability to withstand high and subzero temperatures. Common use cases include aerospace fasteners turbine blades engine components sports equipment and marine applications. Mill Lead Time: As fast as 7 days Finishing options: Media Blasting Tumbling Passivation Grade: Titanium Grade 5

Consult now

With excellent wear resistance and toughness it is often used to make fixtures tools tool holders gauges and punches. Factory delivery time: 7 days. Surface treatment: medium spray tumbling black oxide.

Consult now

ABS is a low-cost engineering plastic widely used for pre-injection molding prototypes. Mill Lead Time: As fast as 3 days Colors: Black neutral matte finish

Consult now

Delrin or acetal is a low-friction high-stiffness plastic material. With a relatively high toughness and minimal elongation Delrin boasts excellent dimensional accuracy. Mill Lead Time: As fast as 3 days Colors: White black brown Grades: 150 AF (13% PTFE Filled) 30% Glass Filled

Consult now

Nylon is a general purpose plastic material that resists both frictional and chemical wear. Two of the most notable use cases for Nylon are in medical devices and electronics insulation notably screws and spacers for panel mounted circuit boards. Mill Lead Time: As fast as 3 days

Consult now

Polyphenylene Sulfide (PPS) is a high-performance engineering plastic with excellent temperature resistance dimensional stability and electrical insulation properties. Mill Lead Time: As fast as 7 days Colors: Natural (off-white)

Consult now

PE is a slippery plastic that is often machined into plugs and seals. It is also an excellent electrical insulator as well as being moisture and chemically-resistant. Mill Lead Time: As fast as 3 days Colors: White black

Consult now

In high-stress or high-temperature applications PEEK is a great lightweight plastic substitute for most soft metals. Additionally PEEK is resistant to moisture wear and chemicals. Mill Lead Time: As fast as 3 days Colors: Opaque beige Grades: Standard PEEK 30% Glass Filled

Consult now

Polypropylene (PP) resists most solvents and chemicals which makes it a wonderful material to manufacture laboratory equipment and containers for a variety of applications. PP also offers good fatigue strength. Mill Lead Time: As fast as 3 days Colors: White (semi-clear or opaque)

Consult now

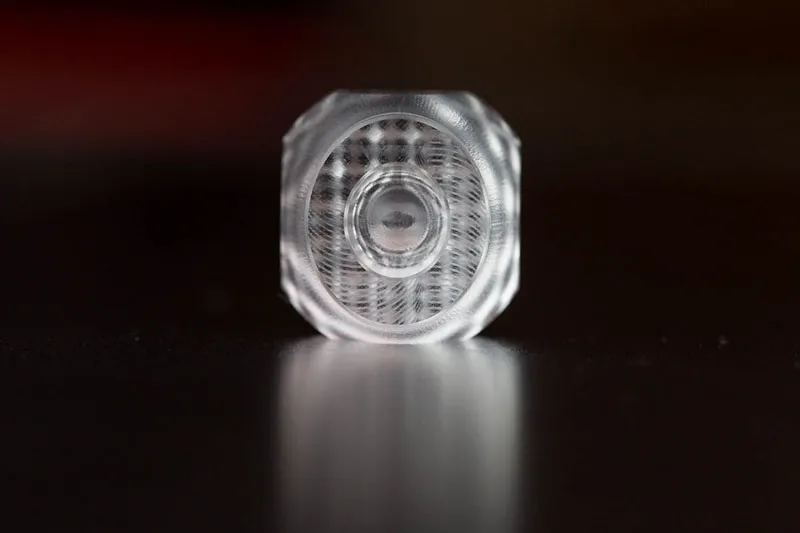

Acrylic is a scratch-resistant plastic material often used for tanks panels and optical applications. Mill Lead Time: As fast as 3 days Colors: Optically clear opaque

Consult now