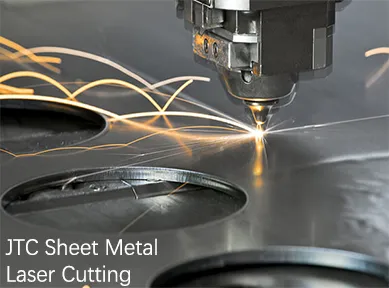

Sheet metal laser cutting is to customize and manufacture specific sheet metal shapes from sheet metal raw materials according to customer design requirements through laser cutting machinery.

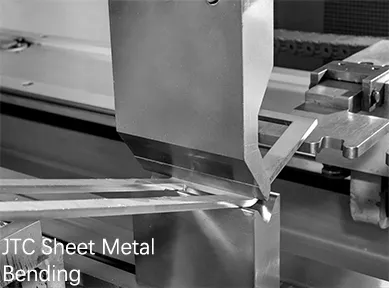

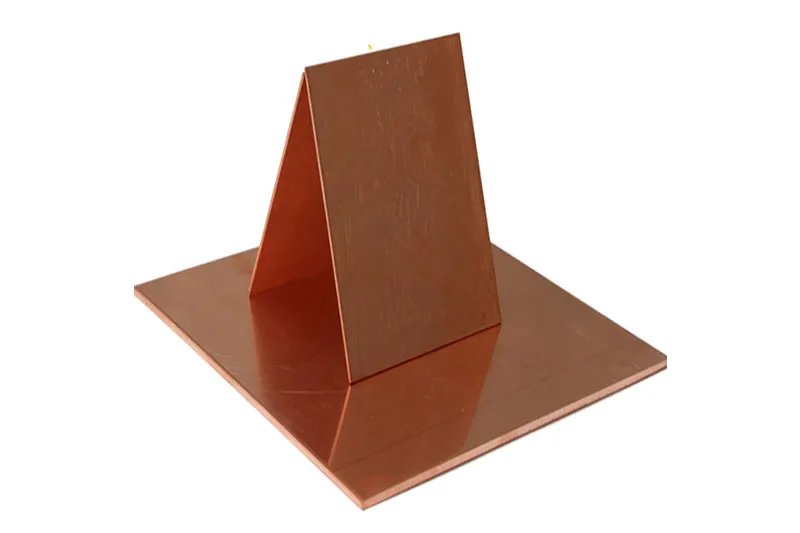

Sheet metal bending: The sheet metal with the bending angle required by the customer is produced by the machine assembled or welded into the finished product.

FDIS09001-2015A

IATF-16949

ISO-27001

FDIS09001-2015A

IATF-16949

ISO-27001

FDIS09001-2015A

IATF-16949

ISO-27001

FDIS09001-2015A

IATF-16949

ISO-27001

FDIS09001-2015A

IATF-16949

ISO-27001

FDIS09001-2015A

IATF-16949

ISO-27001

FDIS09001-2015A

IATF-16949

ISO-27001

FDIS09001-2015A

IATF-16949

ISO-27001

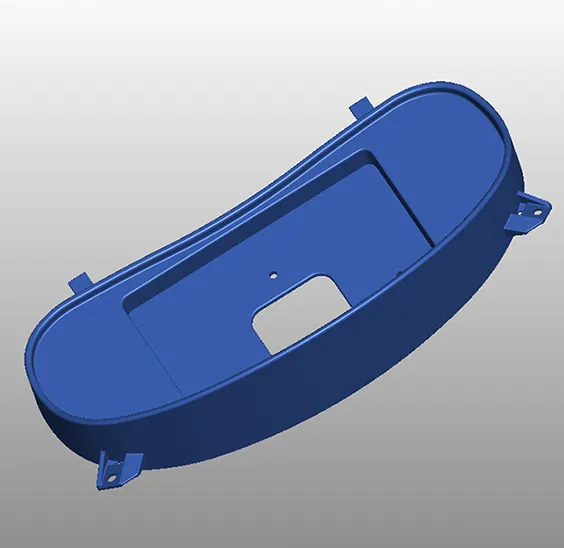

First of all we need to receive your 3D drawings (stp step igs iges format) and quote according to your needs such as quantity material surface finish etc.

Before the mold is assembled to the injection molding machine the drawing needs to be programmed so that we can clearly see the process of the material as it enters the mold for further adjustments and modifications.

According to customer needs we carry out one-stop production and processing processes such as cutting bending perforating sandblasting and polishing of sheet metal.

After the mold is complete it is assembled into the injection molding machine. During the injection process we check that the machine is functioning properly (or not) make some necessary tool adjustments and generate a new sample.

After the samples are surface treated as specified by the customer they will be checked again for dimensions.

According to customer requirements choose the surface treatment method. At the same time quality inspection work is carried out.

The last step is to check whether the mold needs to be adjusted according to the analysis of the sample and whether the test sample meets the previous requirements.

After the samples have been tested to meet the preliminary requirements the samples can be packaged and shipped.

Sheet metal fabrication is a manufacturing method that involves cutting and bending sheets of metal to form different shapes. Sheet metal fabrication is more cost-effective than CNC machining when it comes to metal components with uniform wall thickness.

Laser cutting uses a high powered laser to cut through sheet metal. A series of mirrors and lenses direct and focus a high-energy beam of light onto the surface of the sheet where it is to be cut. When the beam strikes the surface the energy of the beam melts and vaporizes the metal underneath. Any remaining molten metal or vapor is blown away from the cut by a stream of gas. The position of the laser beam relative to the sheet is precisely controlled to allow the laser to follow the desired cutting path.

During the sheet metal fabrication process thin sheet metal stock is placed on a flat bed where a laser cutter (1) draws programmed part patterns. Depending on the part geometry a sheet metal punch (2) can form additional features. Once the parts are deburred they move to the press brake (3) where they are formed into the final geometries. Additional secondary operations are often used to finish the sheet metal parts.

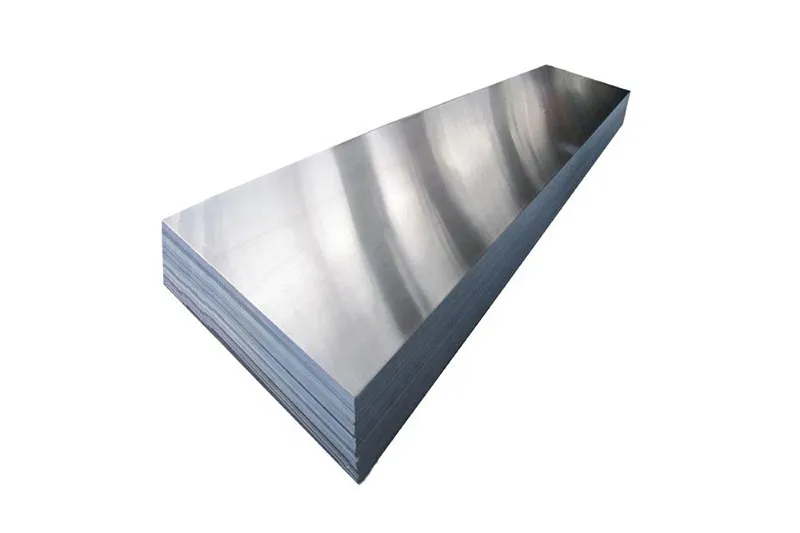

All raw materials for JTC sheet metal production are purchased locally in China and the purity has been strictly tested and can reach more than 95%. Guaranteeing the quality of our products is an important factor for us to stand out.

Work with a trusted China-based manufacturer with capacity and original factory finishing options for your parts. One-stop one to one service lower prices faster delivery. Our clients come from 50+ countries widely.

Aluminum is one of the most commonly used metals in the world because of its excellent strength-to-weight ratio low cost and recyclability.

Consult now

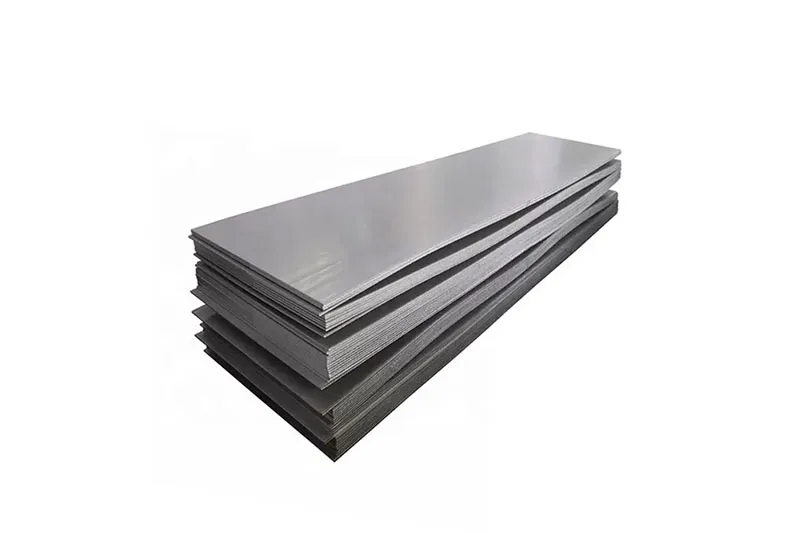

JTC offers both alloy and carbon steel options useful for a variety of applications including fixtures mounting plates draft shafts axles torsion bars gears bolts studs shafts and structural applications.

Consult now

101 and 110 copper alloys offer excellent thermal and electrical conductivity which makes them natural choices for bus bars wire connectors and other electrical applications.

Consult now

Cast iron is a dependable wear-resistant material that’s ideal for absorbing vibrations. Great for gears bases pulleys and bushings.

Consult now

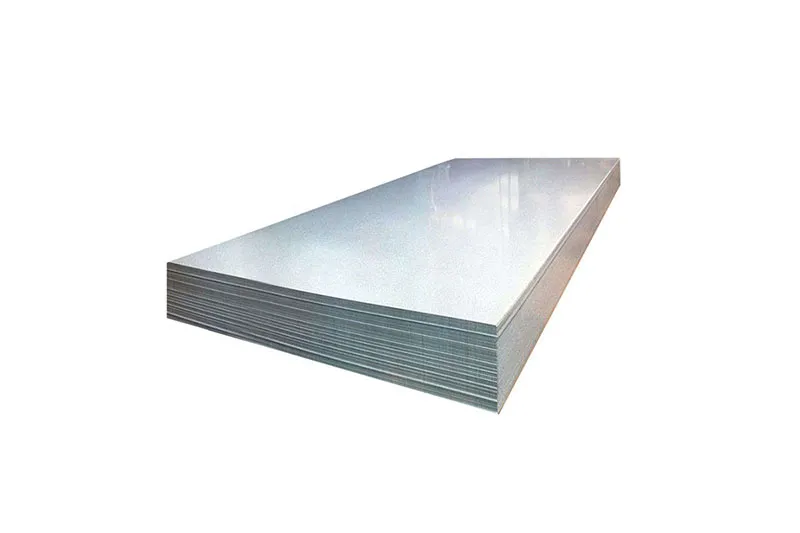

Stainless steel is highly resistant to corrosion and rust making it suitable for situations where a part may be exposed to the elements for long period of time. Stainless steel is also fairly malleable and ductile.

Consult now

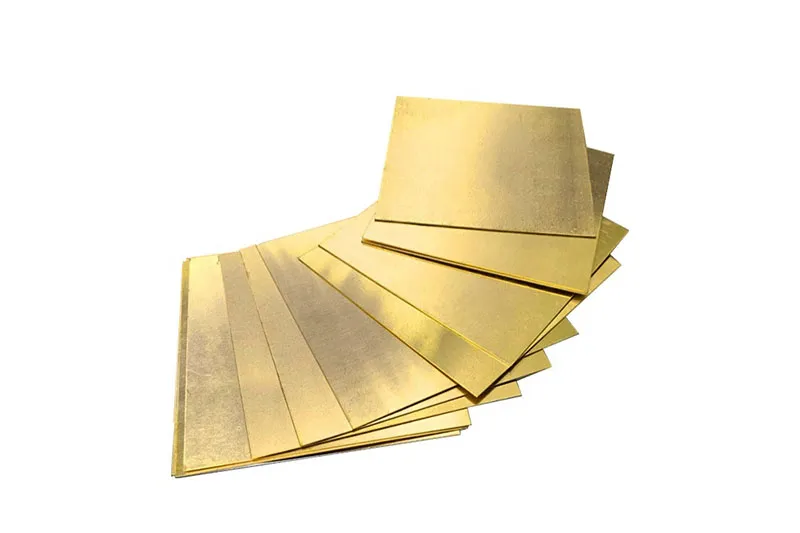

360 Brass also known as free machining brass is commonly used for a variety of parts including gears lock components pipe fittings and ornamental applications.

Consult now

932 Bearing Bronze is a high strength alloy with good wear and corrosion resistance due to its tin iron and zinc content.

Consult now

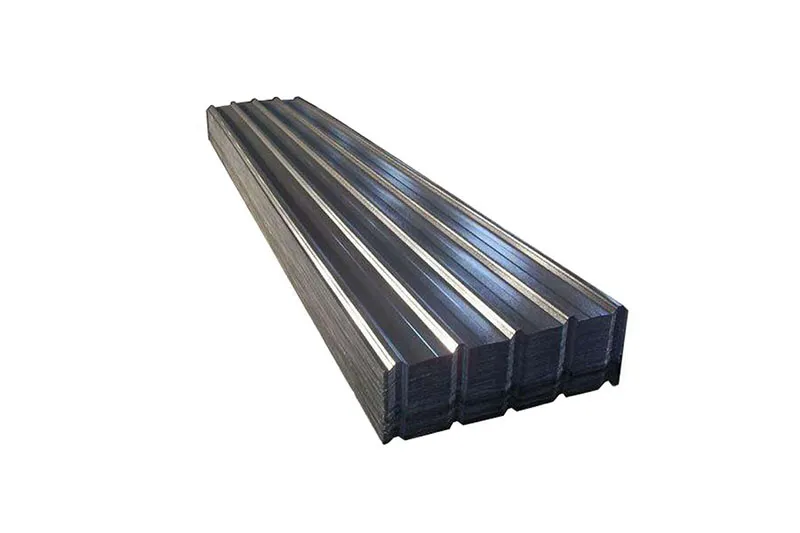

The cold plate is a hot-rolled steel strip of ordinary carbon structural steel which is further cold-rolled into a steel plate with a thickness of less than 4mm. Due to the rolling at room temperature no scale is produced so the cold plate has good surface quality and high dimensional accuracy. Coupled with annealing treatment its mechanical properties and process properties are better than those of hot-rolled steel sheets.

Consult now

High toughness and strong corrosion resistance. SECC can meet the surface finish specification requirements of most sheet metal fittings.

Consult now